At SOFMAN, we take pride in developing innovative solutions to meet our clients’ unique needs by combining structural steel and mechanical components. We also participate in research programs that aim at advancing steel structures as a whole.

research programs

dissipable project

The participants of the Research Consortium:

Between 2018 to 2022, we participated in collaboration with key European Technical Universities in European Funded [RESEARCH FUND FOR COAL AND STEEL] DISSIPABLE project developing and testing dissipative, replaceable components for Steel Buildings

The project aimed to increase the post-earthquake resiliency of steel-concrete composite structures and improve the long-term sustainability of the Steel Building Industry.

Full-scale two-storey composite buildings were constructed within the Laboratory for Earthquake Engineering at NTUA for the project's needs.

Those buildings were then tested under the most severe earthquake scenarios to optimise the performance of the innovative dissipative components included in them.

The Results of the research program were presented in a European e-Workshop that ended with a round table discussion between the research consortium and:

ECCS- European Convention for Constructional Steelwork, Brussels

FONDAZIONE PROMOZIONE ACCIAIO, Italy

FUNDEC–DECivil, Portugal

audit to measure project

We are participating in the EU-funded [LIFE 2021 CET (Clean Energy Transition)] AUDIT TO MEASURE project that aims to lead businesses towards climate neutrality by speeding up the uptake of energy efficiency measures from the energy audits.

The participants of the Research Consortium are shown below:

Partners: RICERCA SUL SISTEMA ENERGETICO - RSE (Italy) SPA, IEECP, INSTITUTE FOR EUROPEAN ENERGY AND CLIMATE POLICY STICHTING (Netherlands), ADELPHI RESEARCH GEMEINNUTZIGE GMBH (Germany), ESCAN SL (Spain), POVAS-PANELLENIA OMOSPONDIA VIOTECHNON ALOUMINOSIDIROKATASKE VASTON (Greece), EPU-NTUA (Greece), HERA SPA (Spain), ENVIROS SRO (Czech Republic), ASOCIACION DE EMPRESARIOS DEL HENARES (Spain), EPIMELITIRIO KORINTHIAS (Greece)

The Research project started in November 2022 and is scheduled to be completed by the end of 2025.

innovative solutions

Our process for creating these intelligent custom-made solutions involves the following ten steps:

-

receiving a request from the client

-

defining the technical characteristics of the new machine

-

examining alternative technical approaches to meet the requirements

-

selecting the optimal solution

-

developing the static and electromechanical design

-

creating a final 3D design

-

constructing the machine

-

conducting tests to ensure proper function

-

certifying the machine according to applicable EU regulation

-

delivering the final product to the client

We have developed a range of machines that cater to diverse needs. Some of these include:

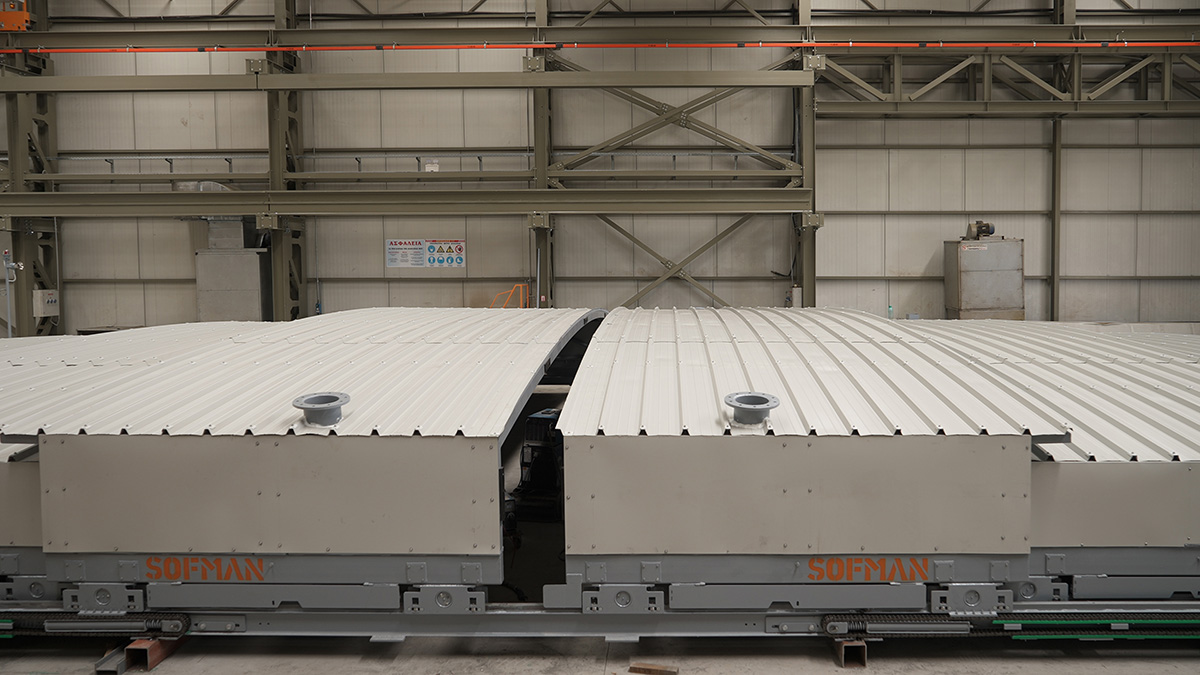

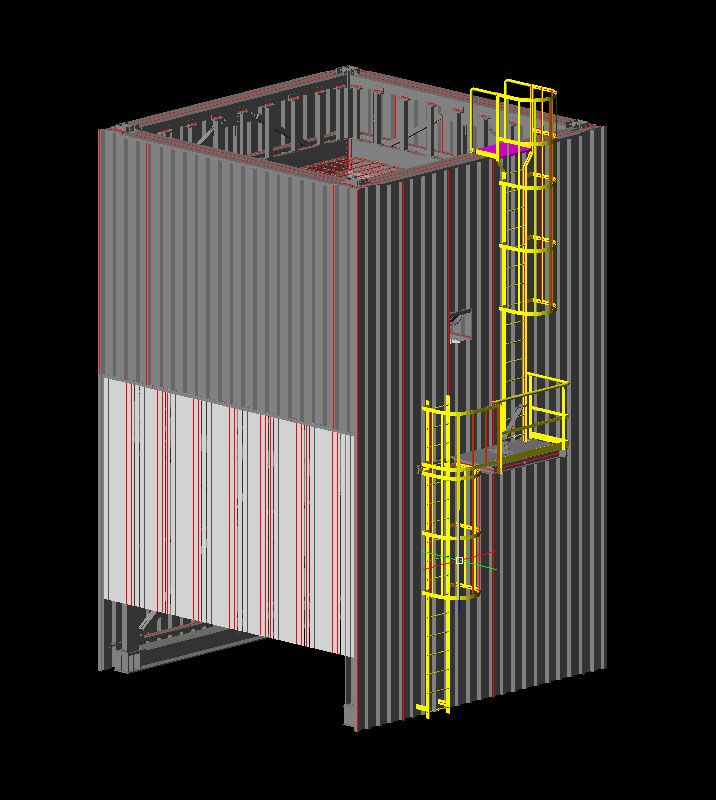

Movable Roof for Biological Aeration Basins

Client: NESTE Rotterdam BV, The Netherlands

Year of execution: 2022

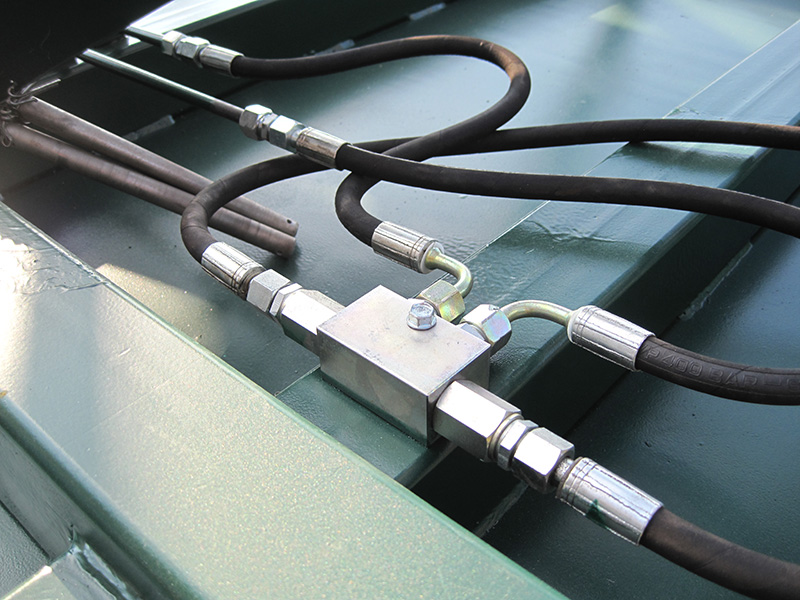

Client’s request: The client has requested the construction of three moveable concrete basin steel roofs that allow the control of the ambient conditions underneath them [air flow, sun exposure, precipitation]. Since the openable roofs were intended for the Oil & Gas industry, all mechanical components should be certified for use in the ATTEX environment.

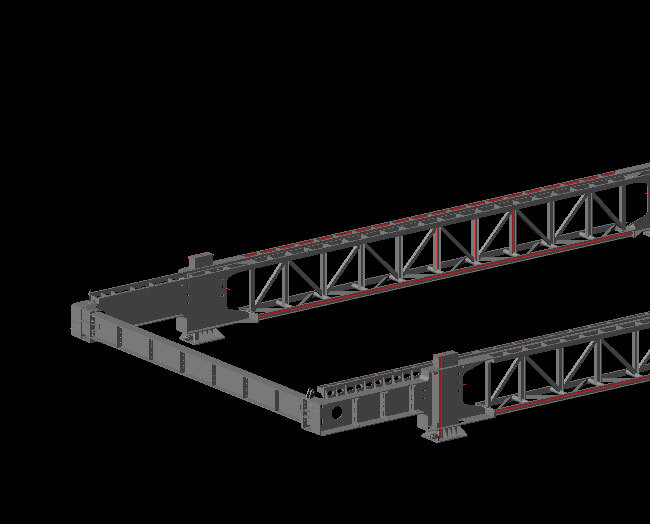

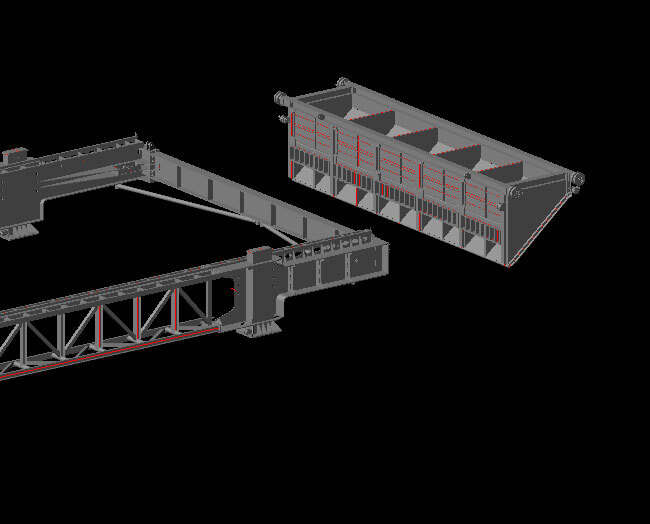

Moveable ship-discharge hopper

Client: LEOCEM, Sierra Leone

Year of execution: 2014

Client’s request: The client has requested the construction of an 80-ton bulk material steel hopper to receive cement, limestone, and other materials from ships. This hopper can be easily transported along the port’s deck and can transfer materials into trucks while minimizing the environmental impact of dust generated during the transfer process.

Quay wall jet – hydro demolition device for underwater use

Client: ARCHIRODON, Morocco

Year of execution: 2013

Client’s request: The client has requested the creation of a steel frame that can move in multiple directions. This frame will be controlled remotely and use HYDROJET technology to remove concrete above and below sea level, up to 4 meters deep.

Device for stratification of seabed

Client: HUTA, Saudi Arabia

Year of execution: 2012

Client’s request: The client has given us the responsibility of constructing a machine that can proficiently perform underwater stratification of the seabed while establishing a new harbor. The machine should function at significant depths of up to 25 meters.

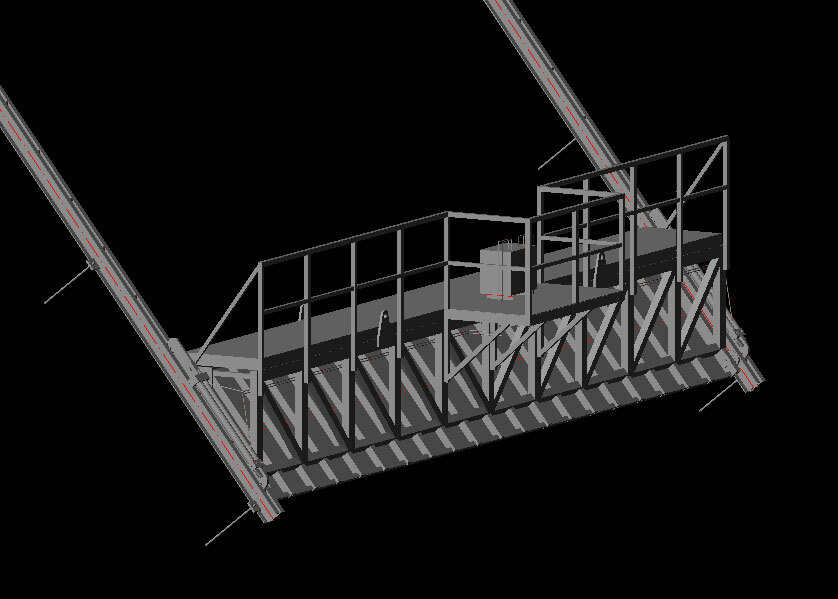

Moveable steel formwork for DAM

Client: OMIROS SA

Execution Year: 2010

Client’s request: The client has requested the construction of a self-propelled metal formwork that can climb by molding a concrete block.